描述

Basic bearing design

Multiple IMCB basic design double row cylindrical roller bearings with different designs are available. The main design differences between bearings are the inner and outer ring retaining edges, as well as the design and material structure of the cage. The most commonly used designs are:

Bearing design, edge arrangement, retaining frame design

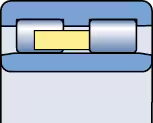

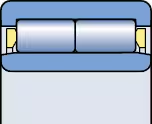

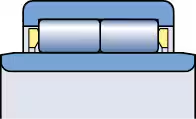

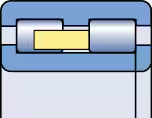

NNU type

Outer ring: Three integral pieces

Inner circle: None

A holder

Machine cut brass or machine cut steel

Double fork type machining cage

Roller centering

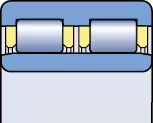

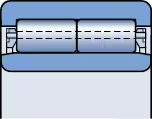

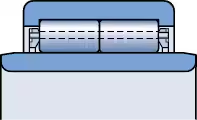

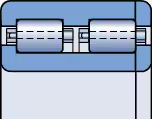

NNU. 1 type

Outer ring: Three integral pieces

Inner circle: None

Two retainers

Machining brass

Window Type

Roller centering

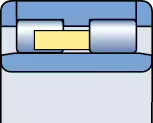

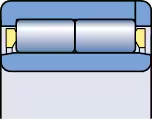

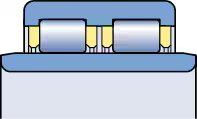

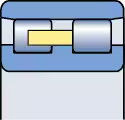

NNU. 2 type

Outer ring: one integral and two movable

Inner circle: None

A holder

Machine cut brass or machine cut steel

Double fork type machining cage

Roller centering

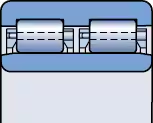

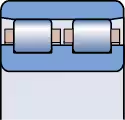

NNU. 3 type

Outer ring: Three integral pieces

Inner circle: None

Two retainers

Machined steel

Selling style

Perforated roller

NNU. 4 type

Outer ring: one integral and two movable

Inner circle: None

Two retainers

Machined steel

Selling style

Perforated roller

NNU. 5 type

Outer ring: Two integral parts

Inner circle: None

A holder

Machining brass

Window Type

Roller centering

NNU. 6 type

Outer ring: Two integral parts

Inner circle: None

A holder

Machined steel

Selling style

Perforated roller

NNU. 7 type

Outer ring: one integral and one movable

Inner circle: None

A holder

Machining brass

Window Type

Roller centering

NNUB type

Outer ring: Three integral pieces

Extended inner circle: None

A holder

Machine cut brass or machine cut steel

Double fork type machining cage

Roller centering

NNUB.1 type

Outer ring: one integral and two movable

Extended inner circle: None

A holder

Machine cut brass or machine cut steel

Double fork type machining cage

Roller centering

NNUB. 2 type

Outer ring: Two integral parts

Extended inner circle: None

A holder

Machining brass

Window Type

Roller centering

NNUB.3 type

Outer ring: Two integral parts

Extended inner circle: None

A holder

Machined steel

Selling style

Perforated roller

NNUB.4 type

Outer ring: Three integral pieces

Extended inner circle: None

Two retainers

Machining brass

Window Type

Roller centering

NNUB.5 type

Outer ring: one integral and two movable

Extended inner circle: None

Two retainers

Machined steel

Selling style

Perforated roller

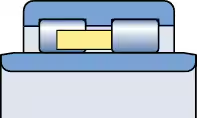

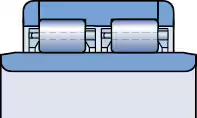

NNUP type

Outer ring: Three integral pieces

Inner circle: one integral and two movable

A holder

Machine cut brass or machine cut steel

Double fork type machining cage

Roller centering

NNUP. 1 type

Outer ring: two integral and one movable

Inner circle: one integral and one movable

Two retainers

Machined steel

Selling style

Perforated roller

NN type

Outer Ring: None

Inner circle: Three integral parts

A holder

Machine cut brass or machine cut steel

Double fork type machining cage

Roller centering

NN.1 type

Outer Ring: None

Inner circle: Three integral parts

Two retainers

PA66 or stamped steel

Window Type

Roller centering

NN.2 type

Outer Ring: None

Inner circle: Three integral parts

Two retainers

Machined steel

Selling style

Perforated roller

NN.3 type

Outer Ring: None

Inner circle: one integral and two movable

Two retainers

Machined steel

Selling style

Perforated roller

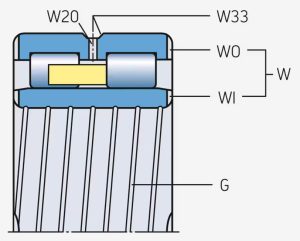

Type/Characteristics

If double row cylindrical roller bearings are to be installed on shafts or support rollers and adopt clearance fit (such as allowing quick roller replacement), one or more additional functions can be provided ( ) to compensate for the drawbacks of clearance fit. The spiral groove in the hole and/or the lubrication groove on the side of the bearing ring provide effective lubrication for the sliding contact surface.

) to compensate for the drawbacks of clearance fit. The spiral groove in the hole and/or the lubrication groove on the side of the bearing ring provide effective lubrication for the sliding contact surface.

Bearings equipped with one or more of these functions are identified in the model/feature (product table) as follows:

G inner ring hole with spiral groove

K-round taper hole

=The taper of K is 1:12

=The taper of K30 is 1:30

Lubrication groove on the side of W bearing ring

WI inner ring side with lubrication groove

WO outer ring side with lubrication groove

W20 outer ring lubrication hole

W33 outer ring with annular groove and oil injection hole

Paired bearings

Combined together, the difference in cross-sectional height of the bearings used in paired bearings is within a very small tolerance range

The prerequisite for reducing tolerance is to narrow the tolerance zone.

The following combinations are available:

Two bearing groups (model suffix DR)

Three bearing groups (model suffix TR)

Four bearing groups (model suffix QR)